Suche

Standorte EKO-Punkt

Hier finden Sie alle EKO-Punkt-Niederlassungen wahlweise als Karten- oder Listendarstellung. Kontaktinformationen inklusive.

Unboxing the Packaging Act –

With EKO-PUNKT

Want to know what surprises the latest round of legal updates of the “VerpackG” holds? We’ve got you covered — with updates and answers to all your questions.

Every Question Answered – Personally

Anyone who has ever visited the official website of the Central Packaging Register (ZSVR) knows how complex the topics of packaging, licensing, and sustainability can be.

At EKO-PUNKT, our goal is to provide you with comprehensive information — without overwhelming you. After all, packaging management should be as easy as possible for you. That’s why we’ve deliberately focused on the essentials when creating the content for our website. This also applies to the FAQ section compiled here. If you don’t find the information you’re looking for, we’re happy to assist you personally at any time — because that’s what we consider real support. Get in touch via contact form or give us a call at +49 221 964897-62.

Information Not Just for Reference – But for Forward Thinking

In this section, we also want to regularly share insights that go beyond classic FAQs — looking toward the future, so to speak. One example is the HolyGrail 2.0 initiative by the European Brands Association. The idea: to mark packaging with digital watermarks, making all material and recyclability information machine-readable — and in turn, enabling better sorting of packaging. Initial test and pilot projects are currently underway in Germany and France. It’s definitely an exciting development, and we’ll continue to monitor it for you.

All related information can be found in the English-language presentation: Pioneering Digital Watermarks

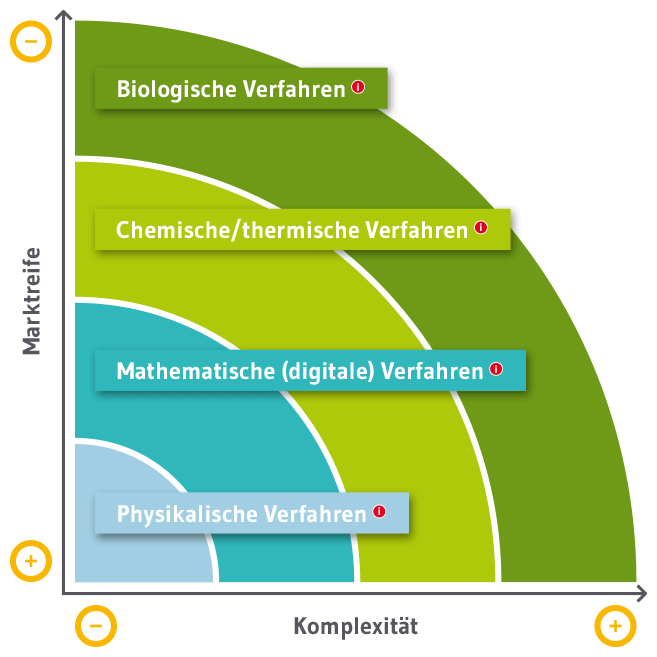

Innovative Processes Gaining Ground — Currently Being Tested

HolyGrail 2.0 belongs to the category of so-called mathematical or digital methods for improving recycling. The technology has proven added value and – unlike experimental approaches such as breaking down PET with bacteria – is already well developed. However, there are also points of criticism. High conversion costs for industry and the recycling sector, in particular, are met with skepticism. It remains to be seen how things will evolve. One thing is certain: recycling technologies are advancing. Below, you'll find an overview of the market situation, including brief descriptions and assessments of the individual approaches.

Dual System and Packaging Licensing - FAQ

Dual Systems are compliance schemes responsible for the collection, sorting, and recycling of packaging waste from private end consumers. They operate in accordance with the German Packaging Act (VerpackG) and are financed by manufacturers and distributors who pay licensing fees based on the amount and type of packaging they place on the market.

The term “dual” refers to the two parallel systems:

- The public waste disposal system (e.g., municipal waste)

- The privately operated Dual Systems, which handle consumer packaging via collection methods like the yellow bin or bag

In Germany, Dual Systems compete in a free market — with multiple providers, including EKO-PUNKT from the REMONDIS Group.

EKO-PUNKT is part of the REMONDIS-Group, giving it the scale and expertise of one of the world’s largest circular economy companies. For customers, this means top-tier quality assurance and, above all, long-term reliability. The market for Dual Systems in Germany is highly competitive. It is very likely that not all of the more than ten current providers will be able to sustain their position in the long run. EKO-PUNKT, however, is certain to remain.

In addition, as a Packaging Competence Center, EKO-PUNKT offers more than just licensing services — including comprehensive solutions across the entire packaging value chain, such as Circular Contracting, Recyclate Supply, and Recyclability Assessments.

Any packaging that ends up with the end consumer and is disposed of via household waste must be licensed, meaning it must be registered with a Dual System.

Legally, the Packaging Act differentiates between sales packaging (e.g., shampoo bottles), outer packaging (e.g., shrink wrap bundling beverage bottles), service packaging (e.g., pizza boxes), and shipping packaging (e.g., cardboard boxes for online orders). However, this distinction is largely irrelevant, as all of these types are subject to licensing requirements.

Even filling materials — such as those used in shipping boxes — must be licensed.

The only current exemption applies to transport packaging, which is used to supply wholesalers and therefore does not reach end consumers. That said, there is a clear trend suggesting this exemption may soon be eliminated, meaning transport packaging will also have to be licensed in the future.

Important: There is no lower threshold for licensing obligations. Packaging must be licensed from the very first gram.

Anyone placing packaging on the market for the first time must complete two steps:

First, they must create an account with the Central Packaging Register (ZSVR).

Second, they must license their packaging — specifying both quantity and material — with a Dual System.

At EKO-PUNKT, this can be done either online using the EASY-LIZE licensing calculator or, for larger volumes, via a customized quote request. System participation is always agreed upon on an annual basis.The licensed annual volume must be reported to the Central Packaging Register — and updated every year.

The Dual System is specific to Germany. If you export packaging to other European countries and it ends up as waste with end consumers there, the packaging must be licensed in each respective country. The process and requirements for international licensing vary from country to country. That’s why we recommend getting personalized advice from us. Learn more under EPR - International Compliance Services.

The early days of the Dual System in Germany revealed several weak points — especially in terms of transparency and fairness. There were repeated instances where producers and distributors found ways to avoid their system participation obligations, gaining an unfair advantage over competitors. The Central Packaging Register (ZSVR) was established to effectively close these loopholes. Its role is to ensure that anyone placing packaging on the market demonstrably takes responsibility for its proper disposal.

Registration with the Central Packaging Register involves two steps.

First, you must create an account for LUCID, the packaging register, using your name, email address, and a password.

You will then receive an activation link for the actual registration process.

The following information is required:

- Name and address of the manufacturer or initial distributor

- Contact details (telephone, fax, email address)

- European or national tax number (VAT ID)

- National registration number (e.g., commercial register or trade license number)

- Brand name under which the packaged products are placed on the market

- Declaration of system participation

Once completed, you will receive a confirmation email from the ZSVR, including your registration number — which is required to license your packaging with a Dual System like EKO-PUNKT.

The following data are published online by the ZSVR in the register of producers:

- Registration number

- Date of registration

- Company details (name, address, telephone number, VAT ID / tax number)

- Information on the packaging

(Are the packaging types subject to system participation or not? What types of packaging are being placed on the market?) - Brand names of the packaging

Packaging Act – FAQ

The most recent amendment to the German Packaging Act (VerpackG) came into force on July 3, 2021. Here are the key changes:

Registration obligation for final distributors of service packaging

Even if service packaging is not placed on the market by the initial distributor and is therefore not subject to system participation, final distributors must register with the ZSVR and declare that they only use pre-licensed service packaging.

Effective from: July 1, 2022

Extension of registration obligation to all producers

All producers of packaged goods are required to register with the ZSVR – especially commercial producers and distributors of:

- Transport packaging

- Sales and outer packaging in the commercial sector

- "Non-compatible" sales and outer packaging

- Packaging for hazardous filling goods

- Reusable packaging

Disposable plastic beverage bottles subject to deposit

Effective from: July 1, 2022

New information obligations

Final distributors of packaging not subject to system participation must inform end consumers about return options and the purpose of proper disposal.

Effective from: July 3, 2022

E-commerce compliance obligation

Online shops may only offer packaging subject to system participation if the manufacturer is registered with a Dual System and listed in the ZSVR packaging register.

Effective from: July 1, 2022

Mandatory recyclate quota for disposable plastic beverage bottles

From January 1, 2025, PET disposable plastic beverage bottles must contain at least 25% recycled content by mass.

From January 1, 2030, this increases to 30%.

Extension of deposit obligations

Almost all disposable plastic beverage bottles and cans (0.1 to 3.0 liters) are now subject to deposit requirements.

Effective from: January 1, 2022

Exception: For milk and mixed milk beverages, the rule applies from January 1, 2024.

Mandatory offer of reusable alternatives

Final distributors/fillers of disposable plastic food packaging or beverage cups (e.g. in the food service sector) must offer a reusable alternative. This must not be offered under worse conditions or at a higher price.

Effective from: January 1, 2023

We will regularly keep you informed about the latest changes to the Packaging Act right here on our website.

To be completely on the safe side, simply subscribe to our newsletter

Under the German Packaging Act (VerpackG), a private end consumer is defined as anyone who discards packaging after use and is not part of the commercial distribution chain. This includes:

- Private households

- Comparable sources of waste generation such as restaurants, hotels, hospitals, schools, offices, small businesses, and farms

- Facilities where packaging waste is collected similarly to household waste (e.g., via the yellow bin or bag system)

These consumers are the final recipients of the packaging and do not pass it on commercially.

Failure to comply with the Packaging Act (VerpackG) can lead to serious consequences.

These include:

- Fines of up to €100,000 for missing or incorrect registration

- Fines of up to €200,000 for not participating in a Dual System

- Sales bans: Non-compliant products may no longer be marketed in Germany

- Public visibility: All registration data are published by the Central Packaging Register (ZSVR), meaning competitors and enforcement bodies can easily identify violations

- Risk of legal warnings (Abmahnungen) from competitors due to unfair market advantage

To avoid these risks, all obligated parties should ensure full compliance with registration and licensing requirements.

The complete text of the German Packaging Act (VerpackG) is available on the official website of the Central Packaging Register (ZSVR) and the German Federal Ministry for the Environment (BMUV). For more information about the German VerpackG have a look here.

For the most up-to-date and legally binding version, visit:

www.verpackungsregister.org

www.gesetze-im-internet.de (official legal portal by the German government)

Please note: The official versions are typically in German. For an English summary or explanation, we recommend referring to our compliance expert get in touch

Recyclates and Recycling – FAQ

The recyclability of packaging can be determined through a combination of material analysis and standardized evaluation criteria.

In Germany, the Central Packaging Register (ZSVR) and the Federal Environment Ministry (BMUV) define a minimum standard for assessing recyclability.

Key factors include:

- Material composition of all packaging components

- Separability of composite materials

- Sorting and recycling behavior in current waste management systems

Presence of additives or contamination that may hinder recycling

At EKO-PUNKT, recyclability assessments can be conducted via lab testing or digital tools such as the PackLab, which creates a digital twin of your packaging and evaluates it against official criteria.

Recyclable packaging plays a crucial role in protecting the environment and conserving natural resources.

When packaging is designed to be recyclable, it can be returned into the material cycle, reducing the need for virgin raw materials such as crude oil, wood, or metal. This helps:

- Lower CO₂ emissions

- Reduce environmental and climate impact

- Meet legal recycling targets (e.g., under the EU Green Deal and the German Packaging Act)

- Enable cost savings through eco-modulation and incentive systems

- Improve brand image by demonstrating sustainability

In short: The more recyclable the packaging, the greater the contribution to a circular economy.

Recyclates are raw materials that have been recovered from used products through recycling processes.

In the context of packaging, this typically refers to Post-Consumer Recyclates (PCR) — materials obtained from consumer waste such as used plastic bottles, films, or paper.

The advantages of recyclates include:

- Reduced use of virgin raw materials (e.g., crude oil, wood, or metals)

- Lower environmental and climate impact through reduced CO₂ emissions

- Compliance with legal requirements (e.g., recyclate quotas under the Packaging Act)

- Support for a circular economy by closing material loops

- Growing consumer demand for sustainable and eco-friendly products

- Potential cost advantages through eco-modulation or funding programs

In short: Recyclates help make packaging more sustainable — both ecologically and economically.

Regardless of their material-specific differences, recyclates can originate from various sources. These include both pre-consumer plastic residues from production processes and post-consumer plastic waste that has been discarded by end users — such as packaging. In Germany, the majority of plastic waste comes from post-consumer material.

Recyclates from this source are referred to as Post-Consumer Recyclates (PCR). To produce high-quality PCR, it is essential that plastic packaging and other plastic products are collected as cleanly and uniformly as possible by consumers and sent for recycling. The purer the input material, the more effectively it can be processed into secondary raw materials. Although this process works quite well in Germany, PCR may only be used for food packaging in a few specific cases. The legislator considers the risk of harmful interactions between packaging and contents too high to allow broader use in the food sector.

Plastic recyclates are generally divided into the following categories based on their origin and processing:

- Post-Consumer Recyclates (PCR):

Recovered from end-consumer waste, such as household packaging (e.g., bottles, films).

→ Most relevant for meeting legal recycling and recyclate targets. - Post-Industrial Recyclates (PIR):

Originating from production waste in industrial processes, e.g., offcuts or defective batches.

→ Usually clean and easy to process, but not counted toward certain recyclate quotas. - Mechanically Recycled Plastics:

Processed through sorting, shredding, washing, and melting — with limited chemical alteration.

→ Most common method in current recycling systems. Chemically Recycled Plastics:

Broken down into basic chemical components and re-polymerized.

→ Allows high-quality output, but still in development and more energy-intensive.

Each category has its own applications, benefits, and limitations — depending on the product, industry, and legal framework.

German legislation relies on a system of incentives and penalties when it comes to the use of recyclates. In the future, manufacturers that use recyclates will likely be rewarded with financial subsidies for doing so. Conversely, poorly recyclable packaging is expected to be subject to penalty charges. In addition, mandatory recyclate quotas will be introduced in the short to medium term. For example, the use of recyclates in the production of plastic beverage bottles will be mandatory starting in 2025.

At present, the use of recyclates in packaging is only partially mandatory — but the legal requirements are tightening.

In Germany and the EU, specific minimum recyclate quotas have already been introduced or planned. For example:

- From January 1, 2025, disposable PET beverage bottles must contain at least 25% recycled plastic by weight.

- From January 1, 2030, this quota increases to 30%.

Further mandatory targets and incentive systems (e.g. eco-modulation of fees) are expected in future packaging legislation — especially as part of the EU Green Deal and the revised Packaging and Packaging Waste Regulation (PPWR). While not all packaging types are currently subject to recyclate quotas, voluntary use of recyclates is increasingly encouraged — and can offer cost and image advantages.

The answer is quick and simple: with EKO-PUNKT. As part of the REMONDIS Group, we have access to large volumes of post-consumer recyclates (PCR) — in any specification you need. Learn more under Recyclate Supply — for those looking to replace virgin materials, improve sustainability, or meet legal requirements, securing access to high-quality recyclates early is key — especially with growing market demand.